Membrane switches have become a fundamental component of a number of electronic devices where the input signal is given physically. From smooth buttons on washing machines to high-end control panels on industrial machinery, these interfaces are essential parts of the functioning of countless devices. Since they have taken over mechanical switches in the last few decades due to their multifaceted benefits, membrane switch manufacturers have grown rapidly. However, the other aspect of this growth is how you would choose one from the many options available if you go searching for a reliable manufacturer of membrane switches. To resolve this issue, here is your essential guide to choosing the top Membrane Switch Manufacturer for your needs.

What is Membrane Switch?

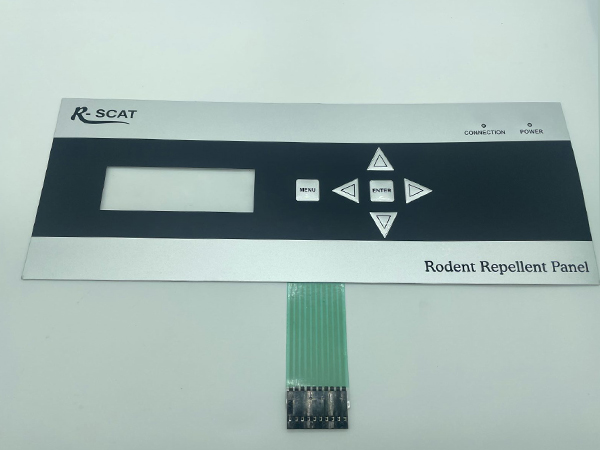

Membrane switch is a thin, layered human-machine interface used to open and close an electrical circuit of an electronic device. It consists graphic overlay, adhesives, and a spacer layer. Compared to mechanical switches, membrane switches have many benefits. It is lightweight, dust, waterproof, requires less material and therefore, it provides a comprehensive advantage of high durability and cost-efficiency.

Being a highly essential component of the human-machine interface, the membrane switch has numerous applications across industries, domestic and commercial. Some significant places where membrane switches are used:

- Consumer Electronics- Washing machine, microwave oven, air conditioner, coffee dispensers, TV remote, etc.

- Healthcare- Diagnostic machine, dental Chair, dialysis machine, monitoring unit, oxygen concentrator, infusion pump, etc.

- Industrial Equipment- Control panels of CNC, cleaning, security systems, testing and measurement systems

- Automotive- Dashboard, air conditioner control panel, keyless entry system

- Aeroplane- Cockpit display, control panels, light control,

Factors to Consider When Choosing a Membrane Switch Manufacturer

A poorly functioning membrane switch can downgrade the whole product, no matter how excellent the rest of the product is. Therefore, choosing the right manufacturing partner to fulfil your demand for membrane switches is vital. Here are key factors to consider when selecting a manufacturer of membrane switches:

Customization: Display is a key part of any membrane switch, as it not only provides convenient usage but also attunes to the brand aesthetics. Every brand has a unique aesthetic and style of presentation to distinguish themselves from others. Therefore, a membrane switch manufacturer should be able to customize the membrane switch display with specific colours, graphics and layout.

Shielding: This is particularly important in scenarios where there is a risk of electromagnetic interference with the switch. In that case, the manufacturer should provide shielding options like carbon ink or aluminium foil.

Accuracy: The membrane switch must be reliable enough to consistently take the correct user input in critical applications such as medical devices, industrial control panels etc. This is ensured by providing tactile or non-tactile feedback options from which users can verify their inputs.

Prototyping Service: Check whether the manufacturer provides the prototyping test of membrane switch with your product before giving order for whole supply.

Years of Experience: Look for the years of experience of the manufacturing in producing great quality, customisable options with consistency for versatile nature of clients.

What Makes Luthra Interface the Best Membrane Switch Manufacturer?

After closely analysing manufacturers on the above parameters, there is a high chance that you would conclude that Luthra Interface is the most reliable manufacturer to partner with. With more than 35 years of experience in manufacturing membrane switches, they have established themselves as a prominent leader in this domain. Here you will get custom-aided designs as per your needs, design flexibility, quality assurance, and durable material, and they cater to a diverse array of clients from healthcare, manufacturing sector, automotive, defence sector, agriculture sector, fitness equipment, domestic appliances and many more.